STANDING

TOGETHER

FOR A SUSTAINABLE

PLANET

TOGETHER

FOR A SUSTAINABLE

PLANET

Recycled capsules and

reborn plantations

reborn plantations

Nespresso has been working towards sustainability

in all its forms for almost 20 years, and it all starts

with recycling. What Else? will show you what happens

to a capsule once it has been used, from the moment

it is collected in store to recasting the aluminium.

in all its forms for almost 20 years, and it all starts

with recycling. What Else? will show you what happens

to a capsule once it has been used, from the moment

it is collected in store to recasting the aluminium.

A NEW LIFE FOR OUR

CAPSULES

CAPSULES

Recovered aluminium is used to

make new products

make new products

What Else? describes every step of the

Nespresso capsule journey once it goes in your recycling bag.

It is the start of a beneficial process that finds a new use

for both the residual coffee and the aluminium.

Nespresso capsule journey once it goes in your recycling bag.

It is the start of a beneficial process that finds a new use

for both the residual coffee and the aluminium.

-

1

1 -

2

2 -

3

3 -

4

4 -

5

5

More than 1000 collection points

A full bag of used capsules is dropped off

at the Delitraiteur in Uccle.

There are 1068 collection points in Belgium and Luxembourg.

at the Delitraiteur in Uccle.

There are 1068 collection points in Belgium and Luxembourg.

“WHENEVER SOMEONE BUYS NESPRESSO COFFEE, WE GIVE THEM A RECYCLING BAG

and explain how they can bring their used capsules back to us.” Behind the counter of the Uccle Delitraiteur, Charlotte Hasevoet is never without her smile, even though she admits that recycling figures could be higher. “Collection is a good habit to get into and can really make a difference if we all do it...” Ella Defoer, a communications student who is fully aware of environmental issues, conscientiously returns her Nespresso capsules. “I sometimes take them back to the boutique near unit, on Avenue Louise, or to the Uccle Delitraiteur, which is near where I live. It’s a simple action that has a huge impact.”

And it’s a habit made all the easier by the range of recycling options Nespresso offers its customers. Between the delivery staff who collect used capsules from your doorstep, or the 1068 collection points in Belgium and Luxembourg, all of the capsules we get back go through a process that both recovers residual coffee for biogas and compost and provides a new life for the aluminium the capsule is made of. Aluminium is the perfect metal for protecting flavours and aromas, and it can also be recycled again and again. Sébastien Vinck, a circular economy expert at the Luxembourg Institute of Science and Technology, highlights that, “We all need to be aware of how important it is to recycle. It’s important for industry, of course, but it’s also important for political decision-makers and consumers”.

and explain how they can bring their used capsules back to us.” Behind the counter of the Uccle Delitraiteur, Charlotte Hasevoet is never without her smile, even though she admits that recycling figures could be higher. “Collection is a good habit to get into and can really make a difference if we all do it...” Ella Defoer, a communications student who is fully aware of environmental issues, conscientiously returns her Nespresso capsules. “I sometimes take them back to the boutique near unit, on Avenue Louise, or to the Uccle Delitraiteur, which is near where I live. It’s a simple action that has a huge impact.”

And it’s a habit made all the easier by the range of recycling options Nespresso offers its customers. Between the delivery staff who collect used capsules from your doorstep, or the 1068 collection points in Belgium and Luxembourg, all of the capsules we get back go through a process that both recovers residual coffee for biogas and compost and provides a new life for the aluminium the capsule is made of. Aluminium is the perfect metal for protecting flavours and aromas, and it can also be recycled again and again. Sébastien Vinck, a circular economy expert at the Luxembourg Institute of Science and Technology, highlights that, “We all need to be aware of how important it is to recycle. It’s important for industry, of course, but it’s also important for political decision-makers and consumers”.

1068

The number of collection points in Belgium and Luxembourg where you can drop off your used capsules. You can drop them off in selected Delitraiteur and UPS stores, and in 17 Brabant Wallon recyparcs, 2 Renewi recyparcs, and soon at Q8 stations. Not to mention your Nespresso boutique, and the DPD drivers who can collect your capsules when making a delivery.

Making it easier to sort waste

Broken up capsules are separated

from unwanted items on a conveyor belt.

from unwanted items on a conveyor belt.

LICHTENVOORDE, IN GUELDRE PROVINCE

IN THE EASTERN NETHERLANDS.

Immaculate cycle paths, brick farmhouses with white shutters and, somewhere on a business park, a rather mysterious factory. Through the door of the Remondis factory, just behind the orderly rows of numbered containers, visitors can discover a series of pipes, conveyor belts, and mysterious cylinders. It’s like a cross between Willy Wonka’s chocolate factory and a giant ball run.

Every day, from 7am to 1am, tonnes of used Nespresso capsules arrive from all over Benelux, as well as from France, where they are passed through this vast machinery system that sorts waste and separates coffee from aluminium. Ella’s bag has also made the journey and is ready to make the giant leap into its new life. The aroma of burnt coffee fills the air. Thijs Bulten, manager of the Lichtenvoorde factory, is fully aware of his mission, and tells us how, “The capsules are tipped onto the first conveyor belt. At the other end, a magnet removes unwanted items: batteries, cans, and pieces of metal...

Anything which ends up here through carelessness or by mistake could damage the system: a simple piece of metal could shut down the whole machine. The capsules are then crushed and filtered. Dry coffee falls to the bottom thanks to gravity, and we collect it in a container”. The remaining damp coffee residue and aluminium then go to a huge dryer, where they are air-dried at 250°C. This dries the remaining coffee so that it can fall though a second filter. Then it’s time for the final part of the process, and Thijs Bulten smiles at a job well done: “Once the aluminium is totally clean, it goes through one final process. It is subjected to ‘Foucault’s’ currents, which separate it from any remaining plastics”.

IN THE EASTERN NETHERLANDS.

Immaculate cycle paths, brick farmhouses with white shutters and, somewhere on a business park, a rather mysterious factory. Through the door of the Remondis factory, just behind the orderly rows of numbered containers, visitors can discover a series of pipes, conveyor belts, and mysterious cylinders. It’s like a cross between Willy Wonka’s chocolate factory and a giant ball run.

Every day, from 7am to 1am, tonnes of used Nespresso capsules arrive from all over Benelux, as well as from France, where they are passed through this vast machinery system that sorts waste and separates coffee from aluminium. Ella’s bag has also made the journey and is ready to make the giant leap into its new life. The aroma of burnt coffee fills the air. Thijs Bulten, manager of the Lichtenvoorde factory, is fully aware of his mission, and tells us how, “The capsules are tipped onto the first conveyor belt. At the other end, a magnet removes unwanted items: batteries, cans, and pieces of metal...

Anything which ends up here through carelessness or by mistake could damage the system: a simple piece of metal could shut down the whole machine. The capsules are then crushed and filtered. Dry coffee falls to the bottom thanks to gravity, and we collect it in a container”. The remaining damp coffee residue and aluminium then go to a huge dryer, where they are air-dried at 250°C. This dries the remaining coffee so that it can fall though a second filter. Then it’s time for the final part of the process, and Thijs Bulten smiles at a job well done: “Once the aluminium is totally clean, it goes through one final process. It is subjected to ‘Foucault’s’ currents, which separate it from any remaining plastics”.

10mn

The time it takes to separate

aluminium and coffee and complete

the first phase of recycling

a used Nespresso capsule.

aluminium and coffee and complete

the first phase of recycling

a used Nespresso capsule.

FULL TRANPARENCY

Nespresso enlisted SGS, an independent body, to carry out an in-depth audit in 2019 of its capsule collection and recycling process. The audit examined Nespresso’s head office, boutiques, and collection points, as well as all of our logistics partners and every step of the recycling process. With the audit complete, SGS gave its stamp of approval to the entire process, in total transparency. This means that all of the capsules that find their way back to Nespresso are really recycled.

Nespresso enlisted SGS, an independent body, to carry out an in-depth audit in 2019 of its capsule collection and recycling process. The audit examined Nespresso’s head office, boutiques, and collection points, as well as all of our logistics partners and every step of the recycling process. With the audit complete, SGS gave its stamp of approval to the entire process, in total transparency. This means that all of the capsules that find their way back to Nespresso are really recycled.

Coffee residue: a source of energy

Coffee residue is mixed

with organic waste to produce biogas.

with organic waste to produce biogas.

SEPARATED FROM THE CAPSULES, THE COFFEE GRINDS ON.

We’re now off to Nimègue, in the Dutch province of Gueldre, a one-hour drive from Lichtenvoorde. The real magic takes place at the back of the building: biomethanisation. That is the technical term for making biogas from the fermentation of organic waste, otherwise known as biomass. The recycling supervisor, Marco van den Hurk, is keen to point out that “Coffee residue has extremely high energy value. It literally boosts the fermentation process. We mix it with compostable waste obtained through sorting programmes. Our bulldozers feed the production chain with a mix of 9% coffee residue (including that from Nespresso capsules) and 91% other organic waste”. The recycling supervisor is razor sharp and deeply passionate about anything to do with green energy. But before fermentation can begin, which takes 14 days in an air-tight container, a final round of sorting is required. Fermentation produces two kinds of gas. First there’s carbon dioxide, which is stored in liquid form and used as fertiliser on farms. Then there’s methane, which is sent to Nimègue where it is repurposed as fuel in the local buses. But that’s not all. Biomass doesn’t disappear once the gas has been made. It is removed from the fermenter and left to dry for two weeks, using equipment to help it air. It is then filtered again to become compost.

We’re now off to Nimègue, in the Dutch province of Gueldre, a one-hour drive from Lichtenvoorde. The real magic takes place at the back of the building: biomethanisation. That is the technical term for making biogas from the fermentation of organic waste, otherwise known as biomass. The recycling supervisor, Marco van den Hurk, is keen to point out that “Coffee residue has extremely high energy value. It literally boosts the fermentation process. We mix it with compostable waste obtained through sorting programmes. Our bulldozers feed the production chain with a mix of 9% coffee residue (including that from Nespresso capsules) and 91% other organic waste”. The recycling supervisor is razor sharp and deeply passionate about anything to do with green energy. But before fermentation can begin, which takes 14 days in an air-tight container, a final round of sorting is required. Fermentation produces two kinds of gas. First there’s carbon dioxide, which is stored in liquid form and used as fertiliser on farms. Then there’s methane, which is sent to Nimègue where it is repurposed as fuel in the local buses. But that’s not all. Biomass doesn’t disappear once the gas has been made. It is removed from the fermenter and left to dry for two weeks, using equipment to help it air. It is then filtered again to become compost.

Plant-based

As of May 2018, a Belgian initiative has made Nespresso capsule recycling bags available in plant-based plastic made using sugar cane. Its lower carbon footprint is another argument for sustainability.

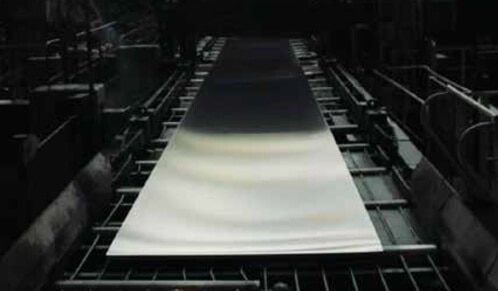

Aluminium can be used forever

The aluminium is heated

to a high temperature,

all the way to its boiling point at 2600°C.

to a high temperature,

all the way to its boiling point at 2600°C.

ALUMINIUM IS ABUNDANT IN THE EARTH’S CRUST.

It is generally extracted from bauxite ore, but the extraction process comes at a relatively high energy cost. However, it pays off in the long term as aluminium is 100% recyclable and recasting use only 5% of the energy used in the initial extraction process. “As is often the case, when we start to think about sustainable development we have to think about the distant future, taking all data into account”, Sébastien Vinck, a circular economy specialist at the Luxembourg Institute of Science and Technology explains:

“Aluminium’s environmental impact varies with its recovery process. The longer it is reused, the smaller this impact becomes. We also need to take the quality of the metal into account, which will determine the way it is used. For this to work, sorting and recycling needs to be taken seriously and meticulously carried out.”

Once they have been broken down into pieces and that the coffee has been cleared out, Nespresso capsules can join the aluminium recycling process. The process starts in a low temperature kiln that removes any finishes and impurities. Only then can recasting proper take place. The metal then goes into another kiln where it is brought to its melting point, at temperatures in excess of 2600°. When it leaves this furnace, the aluminium is spread out into sheets or blocks. It can then be reincorporated into the industrial process, ready for extrusion or injection, and can be used to make car engines, cans, bike parts, pens, or new capsules.

It is generally extracted from bauxite ore, but the extraction process comes at a relatively high energy cost. However, it pays off in the long term as aluminium is 100% recyclable and recasting use only 5% of the energy used in the initial extraction process. “As is often the case, when we start to think about sustainable development we have to think about the distant future, taking all data into account”, Sébastien Vinck, a circular economy specialist at the Luxembourg Institute of Science and Technology explains:

“Aluminium’s environmental impact varies with its recovery process. The longer it is reused, the smaller this impact becomes. We also need to take the quality of the metal into account, which will determine the way it is used. For this to work, sorting and recycling needs to be taken seriously and meticulously carried out.”

Once they have been broken down into pieces and that the coffee has been cleared out, Nespresso capsules can join the aluminium recycling process. The process starts in a low temperature kiln that removes any finishes and impurities. Only then can recasting proper take place. The metal then goes into another kiln where it is brought to its melting point, at temperatures in excess of 2600°. When it leaves this furnace, the aluminium is spread out into sheets or blocks. It can then be reincorporated into the industrial process, ready for extrusion or injection, and can be used to make car engines, cans, bike parts, pens, or new capsules.

95%

The percentage energy saved when making aluminium from recycled products.

A recycled metal pen

Caran d’Ache pens, whose casings

are made of aluminium, are true precision tools.

are made of aluminium, are true precision tools.

IF ELLA SIMPLY PUT HER USED NESPRESSO CAPSULES IN THE BIN

instead of bringing them in for recycling, she would have created more CO2 emission and wouldn’t have helped recover the coffee residue and aluminium. Her actions help fuel green buses, grow plants and vegetables in the fields and on urban rooftop gardens, and even to make things like pens. It is a forceful argument for the young student, who lives in Brussels. True to its Swiss origins, Nespresso has teamed up with Caran d’Ache to revisit one of its flagship products: the 849 pens. Designed in 1969, its unique metal casting and hexagonal shape made it an iconic pen.

In 2018, the first edition made from 25% recycled capsules was made, resulting in an 849-pen adorned in the deep blue of our Dharkan capsules.

In 2019, it is the turn of Master Origin India to get in on the act. Made in the Geneva factory, some 130,000 pens are available in a beautiful deep green. Each one of them will be engraved with the following inscription: “Made using recycled Nespresso capsules”.

Nespresso also keeps an eye on aluminium’s traceability and makes sure that the recycling process counts. An awareness of the impact of each stage is key to sustainable development. Then, it’s up to consumers to play their part and recycle massively to make it a large-scale reality.

instead of bringing them in for recycling, she would have created more CO2 emission and wouldn’t have helped recover the coffee residue and aluminium. Her actions help fuel green buses, grow plants and vegetables in the fields and on urban rooftop gardens, and even to make things like pens. It is a forceful argument for the young student, who lives in Brussels. True to its Swiss origins, Nespresso has teamed up with Caran d’Ache to revisit one of its flagship products: the 849 pens. Designed in 1969, its unique metal casting and hexagonal shape made it an iconic pen.

In 2018, the first edition made from 25% recycled capsules was made, resulting in an 849-pen adorned in the deep blue of our Dharkan capsules.

In 2019, it is the turn of Master Origin India to get in on the act. Made in the Geneva factory, some 130,000 pens are available in a beautiful deep green. Each one of them will be engraved with the following inscription: “Made using recycled Nespresso capsules”.

Nespresso also keeps an eye on aluminium’s traceability and makes sure that the recycling process counts. An awareness of the impact of each stage is key to sustainable development. Then, it’s up to consumers to play their part and recycle massively to make it a large-scale reality.

Signature pieces

The aluminium from Nespresso capsules is used to make a wide variety of products: bikes, soda cans, and pieces made in special partnerships. We can cite, for example, Zena Rex peelers, Victorinox Pioneer penknives, new capsules for Nespresso coffee, and Caran d’Ache pens